|

|

|

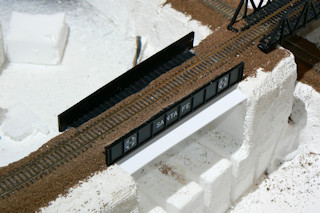

Shown at right is a black steel plate Santa Fe bridge that I will install. I think the two different bridge types right next to

each other will be interesting. The stone abutments will face the tunnels and help support the weight of the 40 ton trains passing

overhead.

|

|

|

Notice that it is very easy to rip away the plaster cloth for remodelling. Also notice that the ballast and black foam bed hold

the track in place with no problems.

|

|

|

Once again there is lots of dust from this operation. Oh well, I guess I am going to be cleaning some track once again.

|

|

|

A train layout is kind of like an oil painting. Sometimes as it develops you come across mistakes or other problems that just

won't work. What is fun is that you have to imagine your own townfolk, and what they would want, and how they would fix it. In

this case, the townfolk have asked for a new tunnel to the factory.In many respects you must be like the artist Bob Ross and put

your happy little trees and tunnels wherever you like.

|

|

|

One of my favorite materials is

30 minute epoxy from Super Glue Corp. This is the company that

also makes Zap a Gap cyano acrylate super glue. I like the epoxy because it is much stronger than super glue and will not weaken

or embrittle over time. The 30 minute working time gives you a little time to work it, hold it, and clamp it into place. The dual

syringe is perfect for dispensing the hardener and resin into a soda bottle cap for mixing the perfect amount.

|

|

|

Sorry, I don't have a final photo with the bridge painted and the stone bridge abutments in place. You will have to search

some of the subsequent photos to see the final results.

Other articles in the scale train series include:

Thanks for reading my articles. More train layout photos and articles will be posted in the near future.