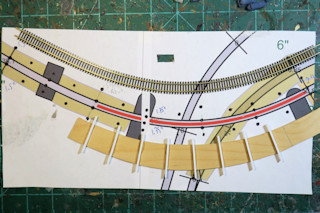

Next I made a template for the bridge.

Luckily the AnyRail software that I used to make the layout can print pages at 100% scale.

For this bridge template I only needs two pages out of the entire 20 page layout.

On top of the template is a piece of Z scale flex track that I formed to follow

the custom curve of the bridge.

The reason I used flex track is that the AnyRail software can form curves

that fit to the adjacent track pieces.

The curve is done with splines which you can shape with control points,

or the software can give you the most gradual curve that fits.

This custom curve does not appear in the Micro Trains Line track product list,

so flex track does the work.

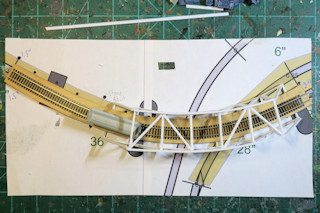

Next I cut the deck of the bridge from basswood plywood. The plywood is about 1/8 inch thick (about 2mm),

and I punctured some holes in the template to transfer the curve to the wood.

Finally I flipped the deck over and glued some scale I-beams from

Evergreen Sale Models to the bottom of the deck.

The I-beams are 1/8th of an inch high (3.2mm) part number 274.

These beams are polystyrene, so liquid model cement works well to hold the plastic together.

These deck supporting I-beams are known as floor beams.

If you would like to learn more about truss bridges, here is

an excellent Wikipedia Truss Bridge article.

This diagram sums up many of

the parts of a truss bridge.